Menu

- About Us

- News

-

Products

- All

- Electric Built-in Guideway Servo Actuator (AU)

- Electric Linear Actuator (JD)

- Electric Cylinder/Mini Linear Actuator (JDR)

- Multi-axis CCD Alignment Stage (XYY)

- Linear motor module/ Optical measuring systems/ Rotor and Stator

- Hollow Rotating Platform (DZ)

- Electric Micro Stage (XBK)

- Manual Micro Stage

- Closed Loop Stepping System (UT)

- Desktop Automatic Locking-screw Machine

- Electric gripper

-

Application

- 5G Component Manufacturer

- Automobile & Electric Vehicle Component Manufacturer

- FDP Manufacturing

- Wafer Manufacturer

- Lens Optics Manufacturer

- Smartphone Component Manufacturer

- LED Manufacturer

- Solar Energy Manufacturer

- PCB Board Manufacturer

- Precision Screen Printing Manufacturer

- Polarizer Laminator Manufacturer

- Glass Substrate Bonding Manufacturer

- 5G Component Manufacturer

- Supports

- E-Catalogue

- Video

-

Download

- Standard Built-in Guideway Ball Screw Servo Actuator-AU

- Clean Room Built-in Guideway Ball Screw Servo Actuator-AUS

- Standard Built-in Guideway Belt Servo Actuator-AUT

- Clean Room Built-in Guideway Belt Servo Actuator-AUTS

- Standard Ball Screw Driven Actuator-JDB

- Clean Room Ball Screw Driven Actuator-JDBS

- Standard Belt Driven Actuator-JDT

- Clean Room Belt Driven Actuator-JDTS

- Electric Cylinder/Electric Micro Putter-JDRN/JDRM

- Multi-axis CCD Alignment Stage-XYY

- Linear Motor Robot-JDLM

- Electric Mirco Stage-XBK

- Electric Gripper

- Contact Us

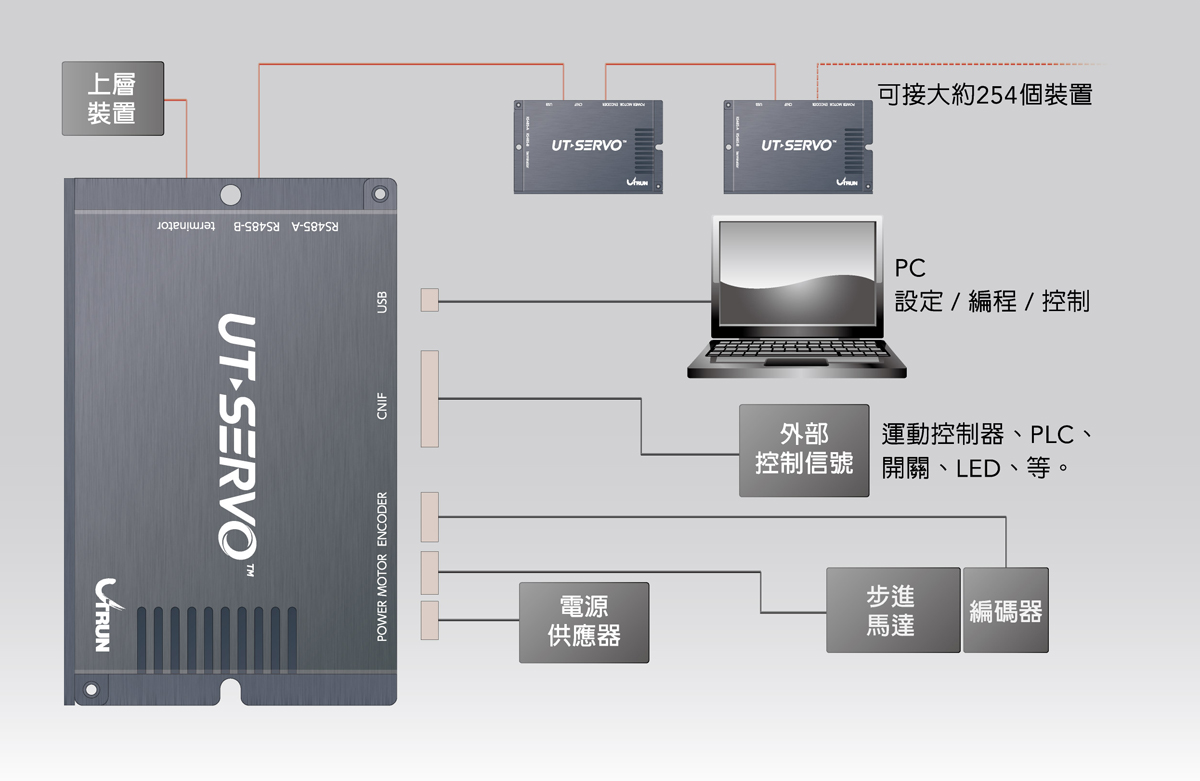

Through the current control technology of UT SERVO, the motor can use the appropriate current to output during the operation process which can greatly reduce waste heat generation and save energy consumption.

Also, UT Series has a unique control technology, effectively reduces the vibration during operation, so does the running noise of the motor.

Features of UT Series Servo Closed-loop Stepping System

- Dynamic adjustment of current and torque without losing a step.

- Low heat generation, low vibration, low noise.

- Easy application and simple setting control.

Torque control function

- Excellent closed-loop control

- Large starting torque

- Precise position control

3 Different Control Modes

- Position

- Torque

- Suppression

With some combination of modes, switching can be completed quickly under the condition of an uninterrupted power supply, providing a very flexible control program.

|

Specification

|

Input voltage | DC24V -5%~+10% | DC48V ±10% |

|---|---|---|---|

| control mode | Position, Torque, Pressing | ||

| Rated output current | Rated 4A | Rated 2A | |

| Max. output current | Max. 6A | Max. 3A | |

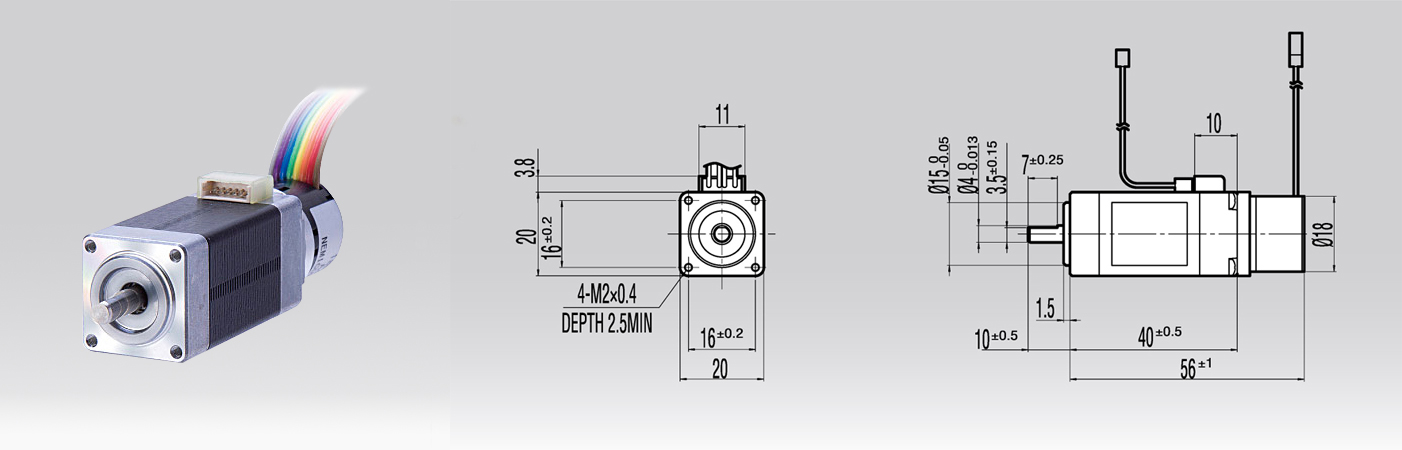

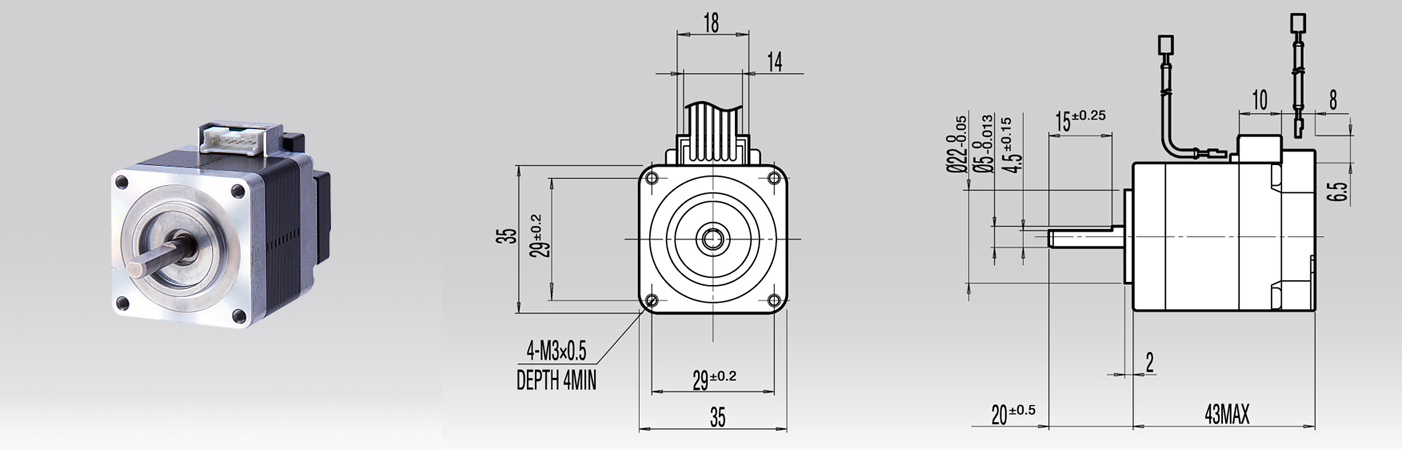

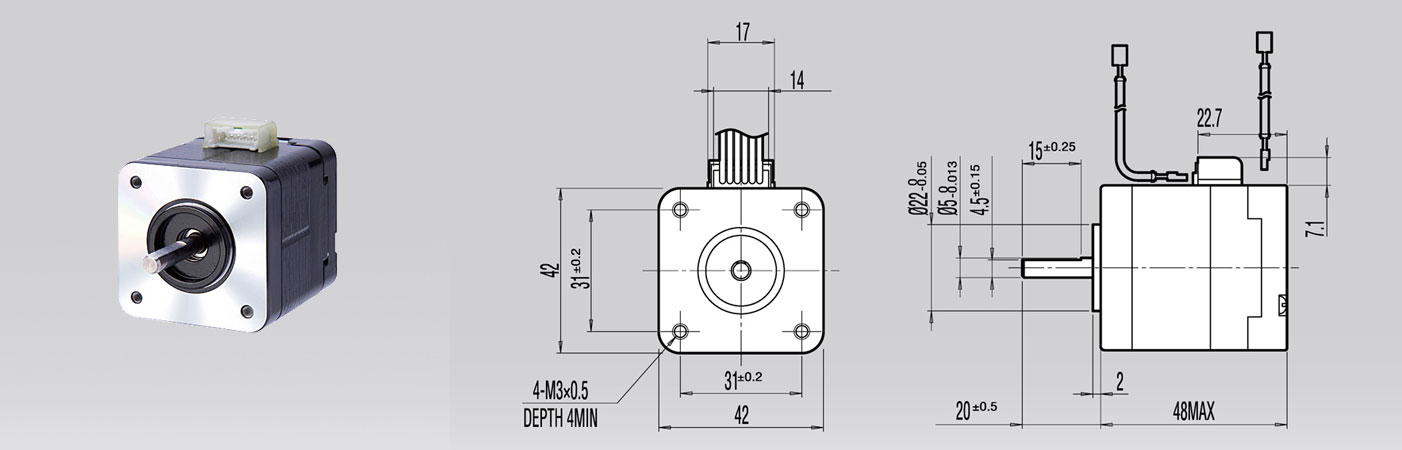

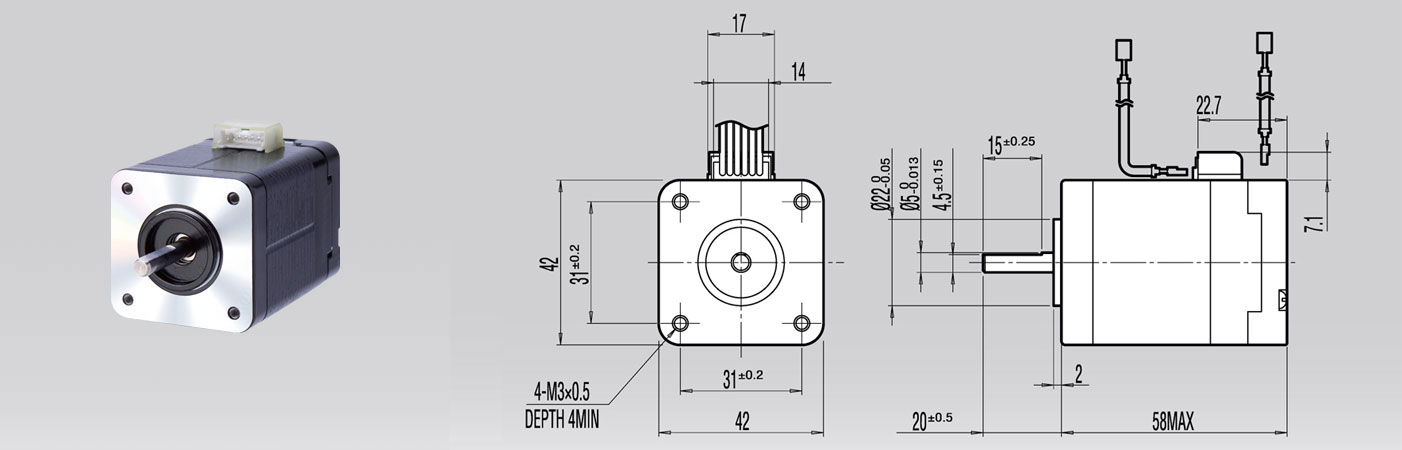

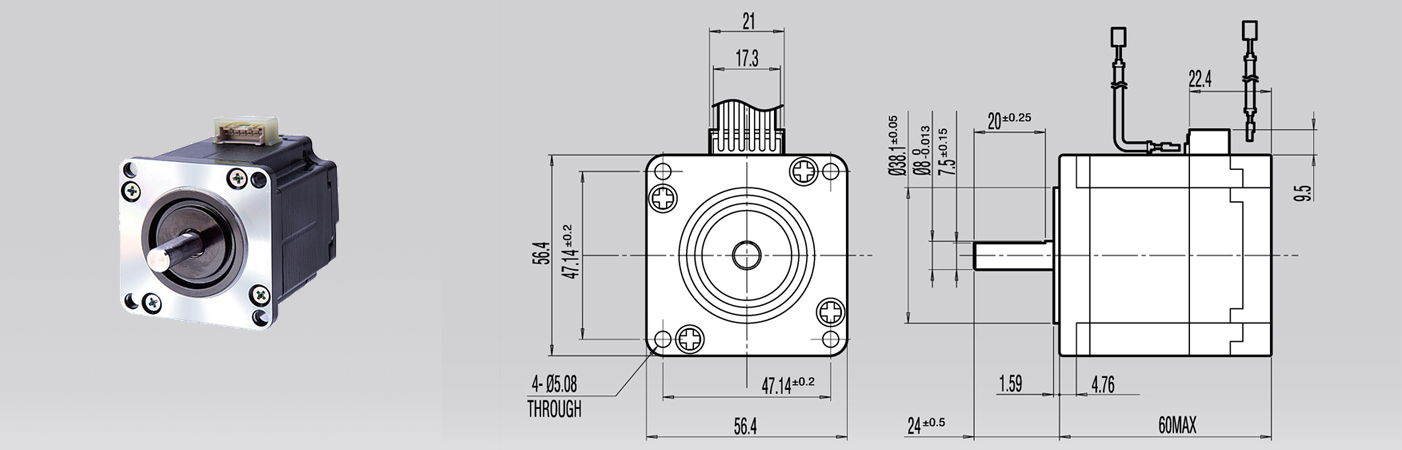

| Applicable motor | Specific motor (20mm、25mm、28mm、35mm、42mm、56mm、85mm) | ||

| Working temperature and humidity | 0℃ ~ 50℃, below 85%RH (No condensation) | ||

| Storage temperature and humidity | -20℃ ~ 85℃, below 85%RH (No condensation) | ||

| Input interface | Digital signal | 10 | |

| Sensor | +LM、LM、ORG | ||

| Output interface | Digital signal | 6 | |

| Brake | Yes | ||

| Control content | Pulse control | Yes | |

| Parameter | Yes | ||

| Built-in program | 64 sets of steps | ||

| Communication interface | USB 2.0 (Virtual COM Port)、RS-485 (RJ-45 Receptacle) | ||

| Communiccation protocol | Modbus ASCLL/RTU | ||

| Exterior | Display | Power LED / Alarm LED | |

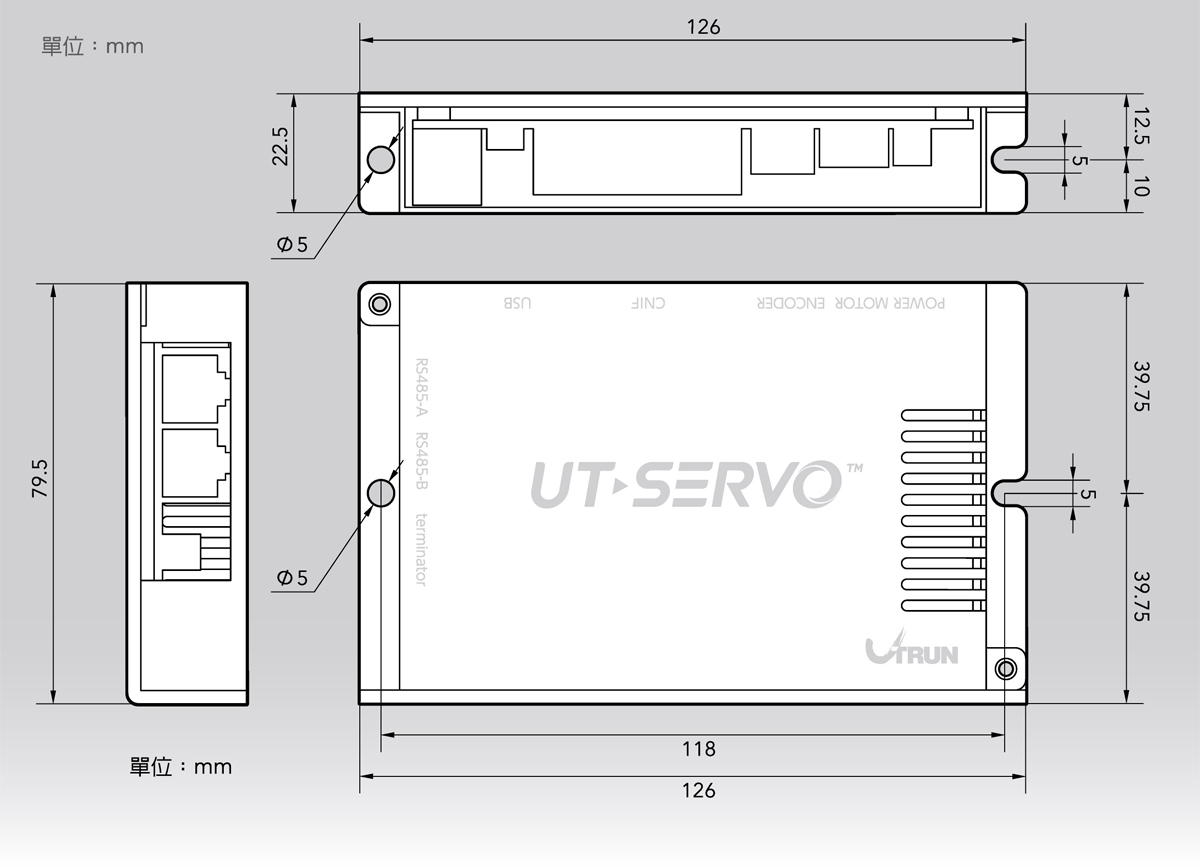

| Size | 126mm(W) X 79.5mm(D) X 22.5mm(H) | ||

| Weight | 170g | ||

|

|

Related Product