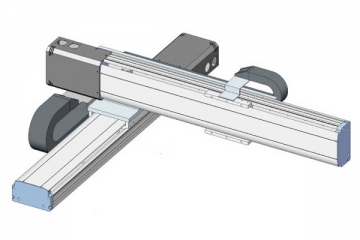

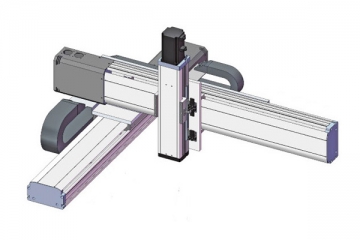

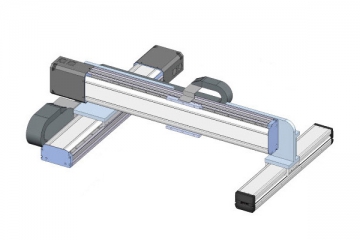

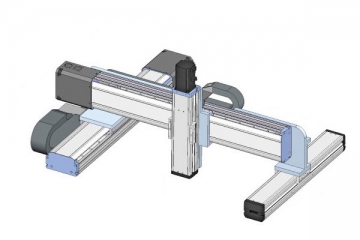

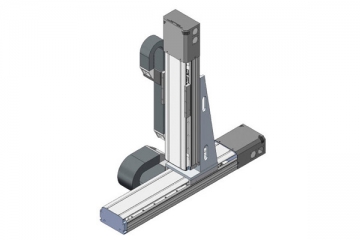

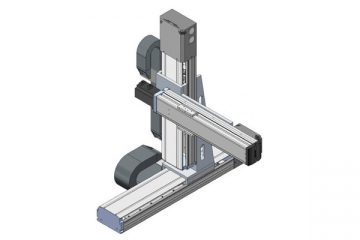

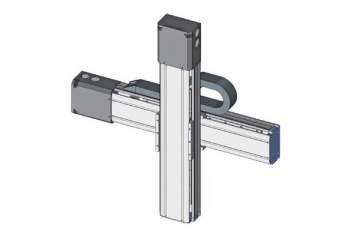

Multi-axis linear actuators, also known as multi-axis actuators or XY actuators, are versatile mechanical systems designed to provide motion in two or more axes. These advanced actuators utilize ball screws or belts, depending on specific application requirements, and can be customized to suit various installation types. Some common configurations include gantry type, cantilever type, vertical type, wall-mounted type, and synchronization mechanism combinations.

Precision Redefined: Harnessing the Potential of 2-Axis and 3-Axis Linear Actuators

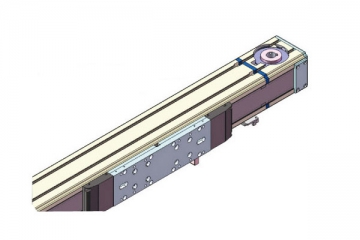

The use of ball screws or belts in multi-axis combined actuators allows for precise and smooth movement across multiple axes. These actuators are pre-engineered to offer bidirectional motion, enabling movement in different planes. Whether you require linear motion in two axes (2 axis actuator) or three axes (3 axis linear actuator), these systems provide the flexibility and performance needed for a wide range of applications.

Unleashing Possibilities: Customizing Multi-Axis Actuators for Optimal Performance

With the advantage of simplicity and versatility, multi-axis driven modular actuators are a reliable choice for industries such as robotics, automation, manufacturing, and precision engineering. Their customizable nature ensures compatibility with specific project requirements, enabling efficient and accurate positioning in complex tasks.

To explore the different types of customization available for multi-axis actuators and discover how they can enhance your application, we invite you to click here. Our range of multi-axis actuation solutions offers precise control, durability, and adaptability to meet the demands of various industries and projects.